On behalf of a modernization of our phone system, our phone number changes. The old phone numbers +49 6406 1509 and +49 6406 6602 (fax) are still available. New numbers +49 6406 92335-0 (main number), +49 6406 92335-170 (fax) and direct access numbers (see contact persons) are now available, too.

Trade show participation: Victam, 31.05.-02.06.2022 in Utrecht

We invite you to visit us on the Victam, 31.05.-02.06.2022 in Utrecht, Stand 02.205 VICTAM International 2022 and GRAPAS Europe 2022 are the world's largest and dedicated events for the animal feed and grain milling & processing industries. The exhibition is a 'one stop' show for the decision makers within...

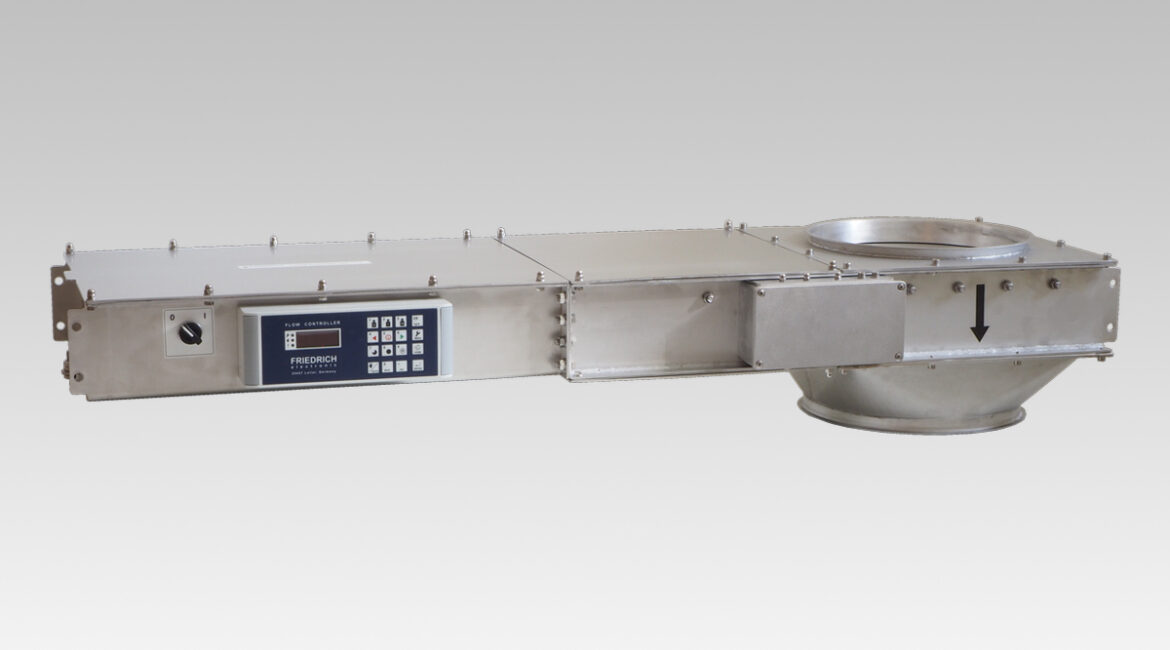

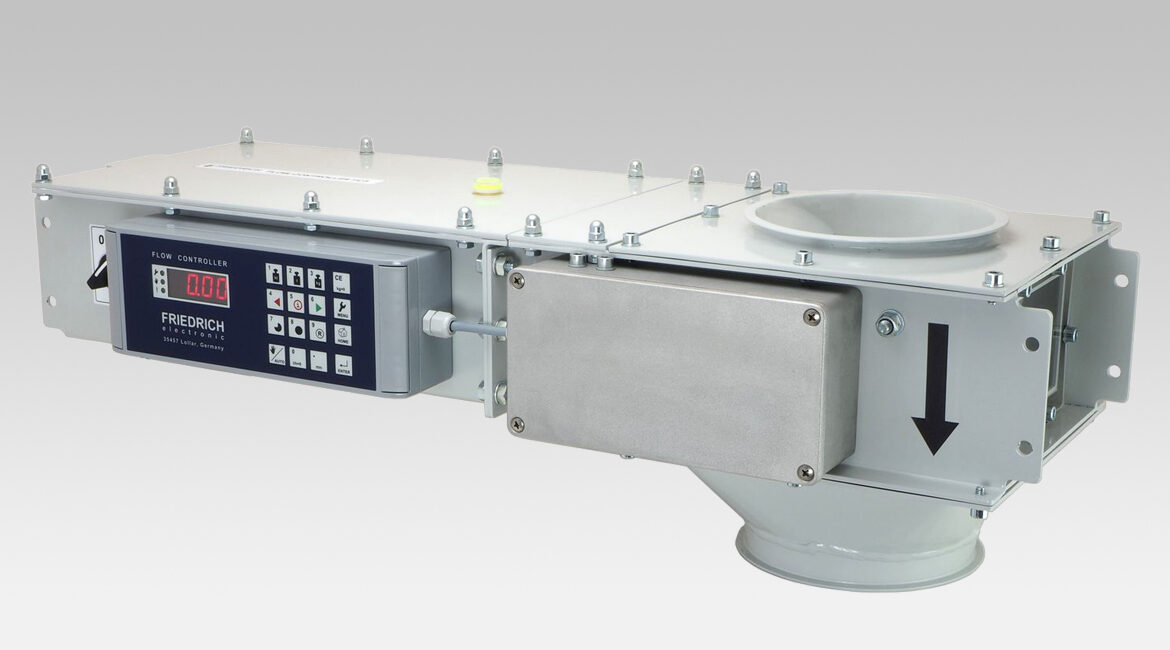

Flow Controller FC3 – series 12 with new features

The new series 12 is available for the Flow Controller FC3. It comes with several new features, which are listed in the following: Reduction of installation height for devices from inlet size DN200 upwards Until now FC3 devices from 200mm inlet diameter upwards had increased installation heights. In case of...

Trade show participation: Victam, 12.-14.06.2019 in Cologne

We invite you to visit us on the Victam, 12.-14.06.2019 in Cologne, Stand E003 VICTAM International 2019 and GRAPAS EMEA 2019 are the world's largest and dedicated events for the animal feed and grain milling & processing industries. The exhibition is a 'one stop' show for the decision makers within...

Flow Weigher DC3 – Compact weighing system for recording of quantities and flow rate of grain

The company FRIEDRICH electronic developed the new weighing system Flow Weigher DC3. It is applied to continuously measure flow capacity and total weight of flowable bulk. The Flow Weigher DC3 is the successor model for the long-standing model type Vertical Pipe Weigher DCG. Several advantages and developments have been implemented,...

The Automatic Dampening System NC8 – modernization of a most successful product

The Automatic Dampening System NC8 – modernization of a most successful product The dampening plays a major role within the grain preparation and cleaning section of a flour mill. It exerts a big influence on the grinding process, since it particularly supports the separation of endosperm and husk. Furthermore the...

Modern dosing systems ensure optimum product flow

Many production processes within the food and feed industry are slowed down by complex and separated dosing and mixing systems. Beyond that, in many cases they suffer high measuring tolerances. Inefficient arrangement of components is often caused by lack of space, which means that gravimetric dosing systems cannot be applied...

2010.03 | Heft 3 Brau Industrie

A small and helpful device between silo and conveyor Usually conveying lines are designed, so that subsequent machines and systems are loaded according to their rated capacity. At the interface between silo and first conveyor there is the discharging section. In cases where a slider is used, the Flow Controller...

2009.09 | Heft 36 Brauwelt

Economic and reliable – Method for regulation of grain moisture. By application of a slider at the interface between silo and first conveyor, the Flow Controller can be applied to set the conveyed capacity in t/h. By continuous regulation it makes sure to convey a steady flow capacity and optimizes...

2008.09 | Verfahrenstechnik

Continuous weighing, dosing and blending Weighing of bulk solids is practically realized by different methods: discontinuous weighing... 2008.09_VerfahrenstechnikDownload