Many production processes within the food and feed industry are slowed down by complex and separated dosing and mixing systems. Beyond that, in many cases they suffer high measuring tolerances.

Inefficient arrangement of components is often caused by lack of space, which means that gravimetric dosing systems cannot be applied directly under the silo cells. In some cases this unnecessarily leads to complex production procedures or compromise solutions, having negative implications on the whole process line.

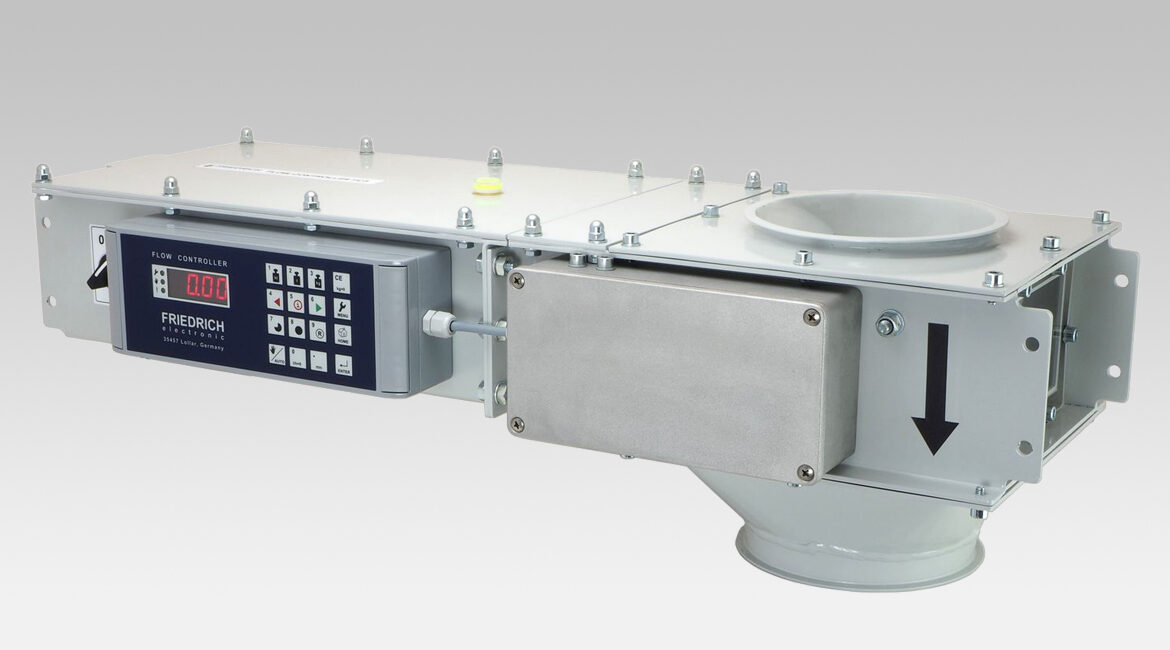

To ensure a smooth operation within process lines of flocks, polenta, pellets or the raw grain, FRIEDRICH electronic developed a flow regulator with electrically driven flat slider, the Flow Controller FC3. Its very low installation height and flared pipe connections allow users to easily integrate the device under the silo bins. Even in most existing plant the device may be integrated without difficulty. Furthermore the device provides useful measuring data, such as actual flow rate in t/h and total amount in kg.

Despite its simplicity and convenience, this gravimetric dosing system reaches continuous target flow rates with measuring tolerances between 0.2% and 2.0%. Linking of a number of Flow Controllers FC3 within the silo plant allows direct mixing of different raw materials within the conveying line and considerably accelerates production processes.

After singular programming of process PLC, it is possible to monitor and supervise errors and incidents of the process remotely. The electronic slider control ensures a secure, automatic 0-taring and checks slider position and weighing signal for plausibility.

Users can quickly and effectively control materials flow rate, access process data and take adjustments by user interface or PLC interface. These characteristics provide maximum process safety and product quality – and valuable information of the process itself. Furthermore the Flow Controller FC3 features an intelligent alarm management system, which automatically identifies errors, e.g. silo empty message, and enables quick resumption of production.

The dosing system is available in different pipe diameters from 120mm to 300mm, reaching flow rate ranges from 1-20 m³/h to 10-200 m³/h. In addition to standard models, FRIEDRICH electronic offers individual customizations, which also contribute and support optimization of processes and conveying lines in world-wide food and feed processing industries.